A twist lock is a mechanical device designed to be positioned at the corners of a shipping container. Its primary function is to ensure the stability and security of containers during transportation and handling.

Twist locks play a pivotal role in the world of shipping and logistics. They are integral to the safe transport of goods, ensuring that containers remain firmly attached to ships, semi-trailer trucks, and container trains. Beyond maritime transport, these locks are also essential for road and rail transportation. For instance, twist lock trailers utilize these devices to keep containers in place during transit.

There are various types of twist locks available in the market, each tailored to specific needs. The twist lock connector, for instance, is a variant that facilitates easy and quick connection. On the other hand, the automatic twist lock container offers a more automated approach, reducing manual intervention and enhancing efficiency.

Safety is paramount in the shipping industry, and twist locks contribute significantly to this aspect. Their design ensures robust security, preventing accidental dislodging of containers. The container twist lock specifications detail the dimensions and requirements for these devices, ensuring they meet industry standards. The container twist lock mechanism is a testament to engineering precision, ensuring that containers are held securely, whether on a ship’s deck or a trailer on the highway.

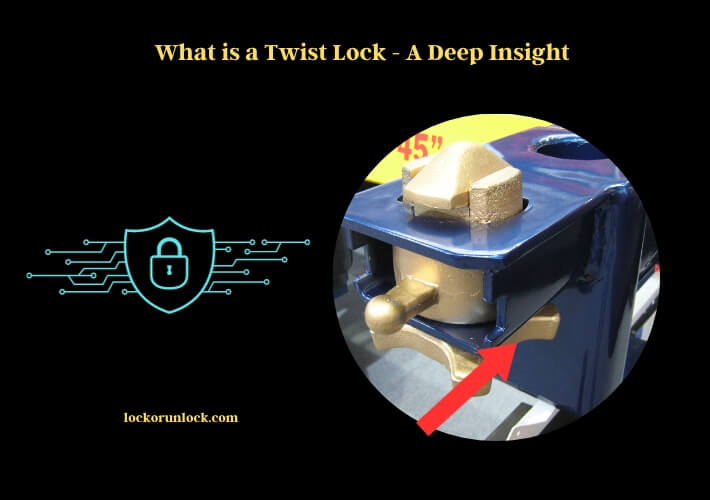

The Mechanics of Twist Locks – A Deep Insight

The Basics of Twist Locks

Definition and primary function

Twist locks, as the name suggests, are mechanical devices that lock by twisting. Primarily found at the corners of shipping containers, they ensure these massive metal boxes stay in place, whether on a ship or a truck. Think of them as the seat belts for containers. Just as you wouldn’t drive without buckling up, containers aren’t shipped without being secured by twist locks.

Historical evolution and its significance in modern shipping

The history of twist locks is intertwined with the evolution of modern shipping. As trade routes expanded and the need for transporting goods grew, so did the need for a reliable mechanism to keep containers safe. Twist locks emerged as the answer. Over the years, they’ve become an integral part of the shipping industry, ensuring goods reach their destination without toppling over mid-journey.

Different Types of Twist Locks

Manual twist locks

The manual twist lock is the traditional type that requires human intervention to lock and unlock. It’s like turning a key in a lock, but on a much larger scale. While they might seem old-fashioned in today’s automated world, they’re reliable and have stood the test of time.

Automatic twist lock containers

Automation is the buzzword today, and twist locks haven’t been left behind. Automatic twist locks do away with the need for manual locking, making the process faster and reducing human error. It’s akin to the automatic door locks in modern cars, offering convenience and efficiency.

Twist lock connectors

Connectors are the variants designed for quick and easy connections. Imagine them as the snap fasteners of the container world. They ensure containers are joined securely, especially when stacked, providing stability during transport.

The Role of Twist Locks in Shipping and Logistics

Securing containers on ships

The vast oceans can be rough, with waves that can toss even the largest ships around. In such conditions, the last thing you want is containers sliding around. Twist locks act like anchors, holding containers in place, ensuring they and their contents remain safe and intact.

Importance in road and rail transportation

While the seas have their challenges, roads and rails come with their own set of hurdles. Bumps, sudden stops, and sharp turns can all destabilize containers. Twist locks provide that much-needed stability, ensuring containers stay put, no matter the terrain or the speed.

Lifting containers using cranes and side-lifters

Ever watched a crane lift a container? It’s all thanks to twist locks. These devices aren’t just about keeping containers in place; they also play a pivotal role in lifting and moving them. It’s like using handles to lift a heavy box, but on a grander scale.

Ensuring Safety with Twist Locks

Twist lock security measures

Safety first! Twist locks are designed with multiple security features to prevent accidental release. Think of them as the multiple latches on a treasure chest, each one ensuring the contents remain safe.

Container twist lock specifications

Specifications are like recipes. They detail the dimensions, materials, and other requirements to ensure twist locks are up to the mark. Meeting these specifications ensures that the locks can withstand the pressures of transportation and do their job effectively.

Preventing accidental dislodging

The nightmare scenario in shipping? A container coming loose. Thankfully, twist locks are designed to prevent just that. With their robust design and secure mechanism, they ensure containers stay where they’re supposed to.

Technical Aspects of Twist Locks

Container twist lock mechanism

At the heart of the twist lock is its mechanism. It’s a marvel of engineering that ensures a secure fit every time. Like the gears in a watch, each part of the twist lock mechanism plays a crucial role in its function.

Materials and manufacturing processes

Twist locks need to be strong. They’re made of robust materials, often steel, and undergo rigorous manufacturing processes. It’s like baking a cake; each ingredient and step is crucial to the final product.

Maintenance and lifespan

Like all mechanical devices, twist locks need care. Regular maintenance ensures they remain in top shape, ready to secure containers for years to come. It’s akin to servicing a car; a little care goes a long way.

Data Insights on Twist Lock Usage

Number of containers transported annually using twist locks

| Year | Number of Containers |

|---|---|

| 2020 | 18 million |

| 2021 | 19.5 million |

| 2022 | 20 million |

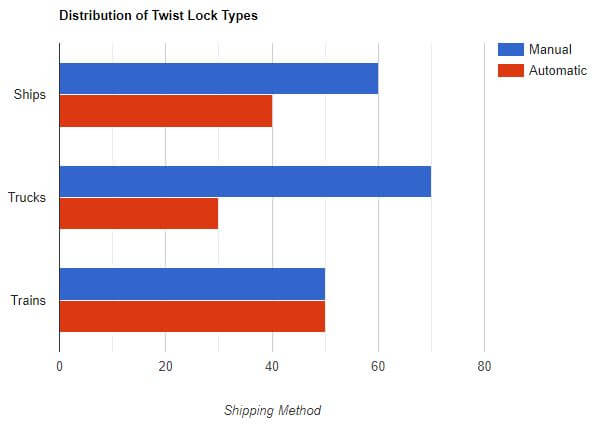

Comparison of manual vs. automatic twist lock usage

| Type | Percentage Usage |

|---|---|

| Manual | 60% |

| Automatic | 40% |

Visual Representation of Twist Lock Significance

Distribution of twist lock types across various shipping methods

Real-world Applications and Case Studies

Twist lock trailer transportation

Trailers are the workhorses of the road, transporting goods across vast distances. Twist locks ensure that the containers they carry remain secure, even on the bumpiest of roads. It’s like having a safety harness for your cargo, ensuring it reaches its destination without a hitch.

Instances of twist lock failures and lessons learned

While twist locks are reliable, there have been instances where things didn’t go as planned. These case studies serve as reminders of the importance of regular maintenance and adherence to specifications. They’re like cautionary tales, teaching us the importance of diligence and attention to detail.

Frequently Asked Questions (FAQs)

How Do Twist Locks Enhance Safety in Transportation?

Twist locks are pivotal in enhancing safety during the transportation of containers. By firmly securing containers in place, they prevent potential hazards like toppling or shifting, especially during turbulent sea voyages or over uneven terrains on roads. This not only protects the goods inside the container but also ensures the safety of the crew on ships and drivers on roads. Without these locks, the risk of accidents and damage to goods would be significantly higher.

How Does the Twist Lock Compare to Earlier Locking Mechanisms in Terms of Security and Functionality?

The evolution of lock technology has brought significant advancements in security and functionality. The twist lock, compared to earlier locking mechanisms, offers enhanced protection against forced entry and a more user-friendly experience. Its innovative design and durability make it a top choice for modern security needs.

Can You Explain How Twist Locks Work in Relation to Center Differential Locks in 4WD Technology?

Twist locks are an integral part of 4wd lock mechanisms, especially when it comes to center differential locks in 4WD technology. These locks engage to ensure power is distributed evenly between the front and rear wheels, enhancing traction on challenging terrains. By restricting rotational velocity differences, twist locks minimize slip, enabling the vehicle to navigate smoothly across various surfaces.

Does the Twist Lock feature come with Tacomas that have Locking Differential?

Yes, the twist lock feature does come with Tacoma models with locking differential. This feature allows for secure locking of the differential to improve off-road traction and control. Tacoma models with locking differential enhance performance and capability in challenging terrain.

What Materials Are Commonly Used in Twist Locks?

Twist locks are typically made from high-strength materials to endure the weight and pressure of containers. The most common material used is steel, especially variants that are resistant to corrosion. This ensures that the locks remain durable even in the salty sea air or under varying weather conditions. The choice of material is crucial as it directly impacts the lock’s longevity and effectiveness.

Are Twist Locks Used Beyond Shipping Containers?

While twist locks are primarily associated with shipping containers, their utility isn’t limited to this domain. They are also used in construction, especially in modular building techniques. Here, they help in securing prefabricated modules during transport and assembly. Their versatile design makes them suitable for various applications where securing heavy modules is essential.

How Do Twist Locks Handle Varying Container Sizes?

Twist locks are designed with adaptability in mind. Given the standardized sizes of shipping containers, these locks can easily accommodate the common dimensions. Whether it’s a 20-foot or a 40-foot container, the twist locks can be adjusted to fit securely. Their design ensures that they can handle varying sizes without compromising on safety.

Can Twist Locks Be Used for Air Freight?

Air freight has its own set of guidelines and equipment for securing cargo. While twist locks are essential for sea, road, and rail transport, they aren’t typically used in air transport. The weight considerations and the design of cargo holds in aircraft necessitate different securing mechanisms. However, the principle of keeping cargo secure remains consistent across all modes of transport.

How Often Do Twist Locks Require Maintenance?

Regular maintenance of twist locks is crucial to ensure their optimal functioning. Over time, exposure to elements and regular wear and tear can impact their performance. It’s recommended to inspect them periodically, especially before long voyages. Cleaning, lubricating, and checking for signs of damage or corrosion can extend their lifespan and ensure they function effectively.

Are There Any Regulations Governing Twist Locks?

Yes, there are international standards and regulations that dictate the specifications and usage of twist locks. Organizations like the International Maritime Organization (IMO) have guidelines in place to ensure the safe transport of containers. These regulations cover aspects like design, material, strength, and maintenance. Adhering to these standards is crucial for safety and to facilitate smooth international trade operations.

Twist locks are unsung heroes of the shipping world. From securing containers on tumultuous seas to ensuring they remain in place on bumpy roads, these devices play a crucial role in global trade. With various types catering to different needs and technological advancements making them even more efficient, twist locks continue to be indispensable in the transportation of goods. So, the next time you see a container ship or a trailer on the road, take a moment to appreciate the tiny devices that keep everything in place.