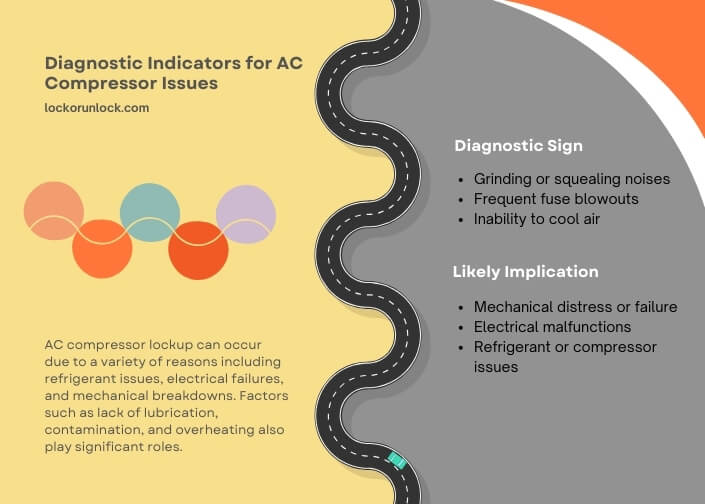

AC compressor lockup can occur due to a variety of reasons including refrigerant issues, electrical failures, and mechanical breakdowns. Factors such as lack of lubrication, contamination, and overheating also play significant roles.

An air conditioning compressor is the heart of the AC system, responsible for circulating refrigerant and maintaining cooling efficiency. Over time, various factors can lead to its failure, significantly impacting the system’s performance. Lack of lubrication is a critical issue; without adequate oil, the compressor’s moving parts face increased friction, leading to overheating and potential seizure.

Refrigerant problems, either from leaks or incorrect levels, can cause the compressor to work harder than designed, increasing wear and the likelihood of lockup.

Electrical failures are another common culprit. Faulty wiring or malfunctioning components can prevent the compressor from starting or operating correctly, leading to its eventual failure. Contamination within the system, such as dirt, debris, or moisture, can also cause significant damage. These contaminants can clog the compressor, reducing its efficiency and leading to overheating.

Regular maintenance is essential to prevent these issues. This includes checking refrigerant levels, ensuring electrical components are in good condition, and replacing air filters to prevent contamination. These potential causes, the lifespan of an AC compressor can be significantly extended, ensuring a cooler, more comfortable environment.

Key Reasons Behind AC Compressor Failures

Air conditioning systems are vital for comfort in homes and vehicles, but their compressors can lock up, leading to significant issues. The heart of the problem often lies in a few critical areas: lubrication deficits, refrigerant complications, electrical malfunctions, contamination, and overheating. Each of these factors can severely impact the compressor’s functionality.

Lack of lubrication can cause increased friction among moving parts, leading to overheating and eventual seizure. Refrigerant issues, whether due to incorrect levels or leaks, can alter the pressure within the system, causing the compressor to work harder than it should, which may lead to failure.

Electrical failures, such as short circuits or faulty wiring, can prevent the compressor from starting or operating correctly. Contamination from external debris or internal system breakdown can clog the compressor, hindering its efficiency. Lastly, overheating, often a result of the above issues, can directly cause the compressor to lock up.

Diagnosing a Locked AC Compressor

Identifying a locked AC compressor involves recognizing key symptoms and using diagnostic tools. Symptoms include unusual noises, such as grinding or squealing, indicating mechanical distress. The compressor may also fail to start, or you might notice the system frequently blowing fuses, pointing to electrical issues. Diagnostic codes from a vehicle’s onboard computer or HVAC system diagnostics can offer clues to the underlying problem.

Diagnostic Indicators for AC Compressor Issues

| Diagnostic Sign | Likely Implication |

| Grinding or squealing noises | Mechanical distress or failure |

| Frequent fuse blowouts | Electrical malfunctions |

| Inability to cool air | Refrigerant or compressor issues |

Preventing AC Compressor Lockup

Preventive maintenance is crucial to avoid the lockup of an AC compressor. Regular checks and maintenance tasks can significantly reduce the risk. These include ensuring the system has the correct amount of lubricant to prevent friction and overheating, checking refrigerant levels to maintain proper pressure and efficiency, inspecting electrical connections to avoid malfunctions, and keeping the system clean to prevent contamination.

AC System Preventive Maintenance Schedule

| Maintenance Task | Frequency |

| Check and refill lubricant | Annually or as needed |

| Inspect for refrigerant leaks | Annually or upon performance drop |

Temperature Extremes and AC Compressor Health

Temperature extremes, both high and low, can adversely affect AC compressor health. High temperatures can cause the compressor oil to degrade, reducing its lubricating properties and increasing wear on components. Low temperatures can lead to refrigerant issues, as the pressure within the system changes, potentially causing the compressor to work inefficiently or lock up.

Making the Repair or Replace Decision

Deciding whether to repair or replace a locked AC compressor involves several factors. Consider the cost of repair versus replacement, the age and efficiency of the current system, and whether the system is under warranty. Often, replacing an older, inefficient compressor with a new, more efficient model can be more cost-effective in the long run, offering better reliability and performance.

FAQs

Can Dirty Air Filters Cause AC Compressor Lockup?

Dirty air filters can significantly impact the performance of an AC system, leading to potential compressor lockup. When air filters are clogged with dust, pet dander, and other debris, airflow is restricted. This reduction in airflow forces the AC system to work harder to circulate air, increasing the strain on the compressor.

Over time, this added strain can cause the compressor to overheat and eventually lock up. Regularly replacing or cleaning air filters is a simple yet effective way to prevent this issue, ensuring the AC system operates efficiently and reducing the risk of compressor lockup.

Is a Locked Up AC Compressor Similar to a Furnace Lock Out Issue?

Yes, a locked up AC compressor is similar to a furnace lockout issue. Both are caused by common causes of furnace lockouts such as a clogged air filter, thermostat issues, or electrical problems. It’s important to address these issues promptly to ensure your heating and cooling systems work efficiently.

Does Frequent Cycling Affect AC Compressor Health?

Frequent cycling, where an AC unit turns on and off more often than usual, can be detrimental to the compressor’s health. This condition puts extra stress on the compressor, leading to increased wear and tear. Each start-up cycle requires a significant amount of energy and generates a surge of electrical and mechanical stress on the compressor.

Over time, this can weaken the compressor, potentially leading to overheating, internal damage, and ultimately, lockup. Addressing issues that cause frequent cycling, such as thermostat problems or incorrect unit size, can help protect the compressor and extend the life of the AC system.

Impact of Incorrect Refrigerant Charge on Compressor

An incorrect refrigerant charge, whether too much or too little, can have severe consequences for an AC compressor. An overcharged system puts excessive pressure on the compressor, leading to increased mechanical stress and higher operating temperatures.

Conversely, an undercharged system causes the compressor to work harder to achieve the desired cooling effect, which can also lead to overheating and eventual lockup. Ensuring the refrigerant charge is precisely calibrated according to the manufacturer’s specifications is crucial for maintaining compressor health and preventing lockup.

Role of Defective Components in Compressor Lockup

Defective components within the AC system, such as faulty capacitors, damaged fan motors, or worn bearings, can lead to compressor lockup. These components are essential for the efficient operation of the compressor; for example, capacitors help start the compressor, while fan motors dissipate heat from the system.

If these parts fail, the compressor can overheat or experience excessive mechanical stress, leading to lockup. Regular inspections and timely replacement of worn or defective components are vital to prevent compressor lockup and ensure the longevity of the AC system.

How Does System Age Influence Compressor Failure?

The age of an AC system can significantly influence the likelihood of compressor lockup. As the system ages, components wear out, and the efficiency of the compressor can decline. Wear and tear over years of operation can lead to issues such as internal component degradation, lubricant breakdown, and increased susceptibility to damage from other system failures.

Older systems may also be more prone to refrigerant leaks and electrical issues, further increasing the risk of compressor lockup. Regular maintenance and timely upgrades or replacements of aging systems can help mitigate these risks.

Can Power Surges Cause AC Compressor Lockup?

Power surges are sudden, brief spikes in electrical voltage that can damage the AC compressor. These surges can occur due to lightning strikes, power outages, or fluctuations in the electrical grid. When a power surge hits an AC unit, it can overload the compressor’s electrical components, leading to immediate damage or weakening them over time.

This damage can increase the risk of compressor lockup. Installing surge protectors or a whole-home surge protection system can safeguard the AC unit from the damaging effects of power surges, helping to prevent compressor lockup and extend the system’s lifespan.

Summary

AC compressor lockup can stem from various issues, including lubrication problems, refrigerant imbalances, electrical failures, contamination, and overheating. Recognizing the symptoms early and employing preventive maintenance can help avoid costly repairs or replacements. Temperature extremes also play a significant role in compressor health. Making an informed decision on whether to repair or replace a locked compressor depends on cost, age, efficiency, and warranty considerations.