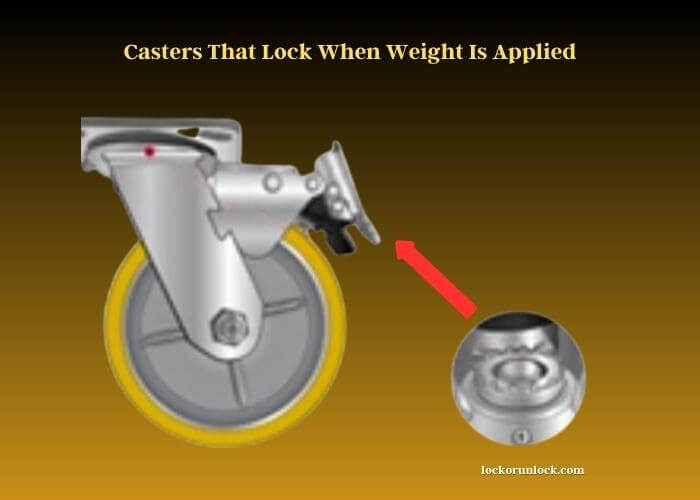

Compression brake casters prohibit rolling as weight is applied. Decompression safety casters prohibit rolling with no weight applied to seating.

Lockable casters provide a solution to controlling movement in various applications, such as furniture, medical equipment, or industrial machinery. These casters often utilize weight-sensitive technology, where the application of a load triggers a braking mechanism. This pressure-activated system ensures stability by creating friction between the wheel and its contact surface. When a particular weight is placed on the caster, the brake engages, making it a perfect feature for both safety and convenience.

In contrast, decompression safety casters function in the opposite way, prohibiting rolling when there is no weight on the seating. The lack of pressure disengages the brake, allowing free movement. Both compression and decompression safety casters contribute to overall mobility and control.

The concept of lockable and weight-sensitive casters combines load-bearing capacity with precise control over movement. These wheels offer the ideal balance between stability and mobility, ensuring that the equipment or furniture stays firmly in place when needed but can also be easily moved. Their design is an essential innovation in providing secure and adaptable support for various objects and scenarios.

Brakes in Motion: A Guide to Casters that Lock with Applied Weight

Mechanism Behind Casters that Lock with Weight

Physics of Locking

Casters that lock with weight are built with intricate mechanisms. These devices detect weight and instantly engage a brake, halting movement. The principles involved are lever systems, friction, and force distribution, which together ensure a prompt response.

Types of Weight-Sensitive Locking

Different designs cater to different needs. Some models may employ hydraulic systems, while others might use mechanical levers. The choice depends on the expected load and required responsiveness.

Compression Brake Casters

Definition and Function

Compression brake casters use the applied weight to compress a braking mechanism, inhibiting movement. This type of caster is commonly used in applications where stability is paramount.

Benefits and Limitations

These casters are robust and offer excellent stability but might be slow to respond or require significant weight to engage. They might not be suitable for lighter loads.

Comparison of Various Compression Brake Casters

| Model | Response Time | Weight Requirement | Price |

| Compact Model | Fast | Medium | $$ |

| Heavy-Duty | Slow | High | $$$ |

| Lightweight | Moderate | Low | $ |

Decompression Safety Casters

Definition and Function

Decompression safety casters work inversely to compression brake casters, disengaging the brake as weight is applied. They are common in seating, ensuring chairs remain stationary until used.

Pros and Cons

This system provides a unique advantage in mobility but might be tricky to fine-tune. Too little weight might not disengage the brake, and too much could wear the system faster.

Applications for Decompression Safety Casters

| Industry | Typical Use | Benefits | Drawbacks |

| Healthcare | Patient Beds | Ease of Mobility | Cost |

| Office Spaces | Chairs | Stability | Tuning |

| Retail | Shopping Carts | Customer Convenience | Maintenance |

Comparison between Compression and Decompression Casters

Key Differences

While compression brake casters lock with weight, decompression safety casters do the opposite. The former finds usage where stability is key, while the latter offers unique advantages in mobility.

Situational Preferences

Selecting between the two depends on the specific needs of an application. Compression may be better for heavy machinery, while decompression suits everyday furniture.

Cost Considerations for Both Types

| Type | Initial Cost | Maintenance Cost | Longevity |

| Compression Brake Casters | $$$ | $$ | Long |

| Decompression Safety Casters | $$ | $$$ | Moderate |

Industries Utilizing Locking Casters

Healthcare

Locking casters are essential in healthcare for patient beds, enabling quick movement and stable positioning.

Manufacturing

In manufacturing, these casters allow for the secure positioning of heavy machinery, contributing to safety.

Retail

In the retail industry, shopping carts and display stands benefit from casters that lock with weight, offering convenience and stability.

Safety and Compliance

Regulatory Measures

Various standards govern the design and usage of locking casters. Compliance ensures both performance and safety.

Best Practices

Proper installation, regular inspection, and timely maintenance are vital for optimal performance and safety.

Consumer Buying Guide

Selection Criteria

Choosing the right casters requires consideration of factors like load capacity, responsiveness, floor type, and intended use.

Installation Tips

Proper installation requires alignment, secure fastening, and testing to ensure proper function.

Maintenance and Care

Regular cleaning and lubrication ensure longevity and consistent performance.

Future Developments and Trends

Technological Advancements

New technologies are driving innovations in caster design, offering enhanced performance, and reducing costs.

Sustainability Efforts

Eco-friendly materials and designs are becoming more prevalent, aligning with global sustainability goals.

Market Analysis

The demand for specialized casters continues to grow, influenced by trends in automation, healthcare, and retail.

FAQs

What Are Brake-When-Loaded Office Chair Casters?

Brake-when-loaded office chair casters are specific types of casters designed to lock the wheels when a certain weight is applied, usually in office chairs. This ensures stability during use.

How Do Weight-Sensitive Casters Contribute to Rear Wheels Locking Up?

Weight-sensitive casters play a crucial role in preventing the issue of locking up rear wheels. By distributing the weight more evenly and adjusting the pressure on the rear wheels, these casters help to minimize the risk of locking up rear wheels, leading to smoother and safer mobility.

Can Shepherd Wheels and Casters Be Used with Self-Locking Mechanisms?

Yes, Shepherd is a popular brand that manufactures various types of wheels and casters, including those with self-locking mechanisms. They offer different models to fit various applications.

Why Are Self-Braking Casters Preferred in Some Industries?

Self-braking casters offer enhanced safety and control as they automatically engage the brake when a certain weight is applied. This makes them suitable for applications where precision and stability are required.

Are Weight Activated Locking Casters Suitable for All Types of Furniture?

Weight activated locking casters are highly versatile but may not be suitable for all furniture types. It’s essential to match the caster’s specifications with the furniture’s weight and usage requirements.

Where Can I Buy Shepherd Casters?

Shepherd casters are widely available through various online retailers, specialty stores, and hardware shops. You can also purchase them directly from Shepherd’s official website or authorized distributors.

How Do Compression Brake Casters Work?

Compression brake casters operate by using the weight applied to compress a brake mechanism. This compression action causes the caster to lock, thus prohibiting any movement. They are often used where stability is crucial.

What Is the Difference Between Sit-Brake Casters and Self-Locking Casters?

Sit-brake casters typically lock when weight is applied, like when someone sits on a chair. Self-locking casters, on the other hand, can have various locking mechanisms, including manual locking or weight-activated systems, giving them broader applications.

Read More: